XTPL to supply a module for industrial implementation to China’s leading manufacturer of machinery for the FPD industry

XTPL is conducting a fifth sale of a module for industrial implementations. The end client is a leading Chinese manufacturer of machinery for the Flat Panel Display (FPD) industry. XTPL’s relationship with the client was launched by an official distributor of XTPL solutions in the Chinese market, Yi Xin Technology. The initial evaluation process for the technology, which culminated in a decision to purchase the module, spanned approximately five months. The module intended for industrial integration is scheduled for delivery within 3–5 months, which will be followed by the building of the industrial prototype of a device with the XTPL module embedded in it. The most important clients of the end buyer include, among others: a global Chinese player listed on the Shenzhen Stock Exchange, with annual revenues in the order of several tens of billion USD.

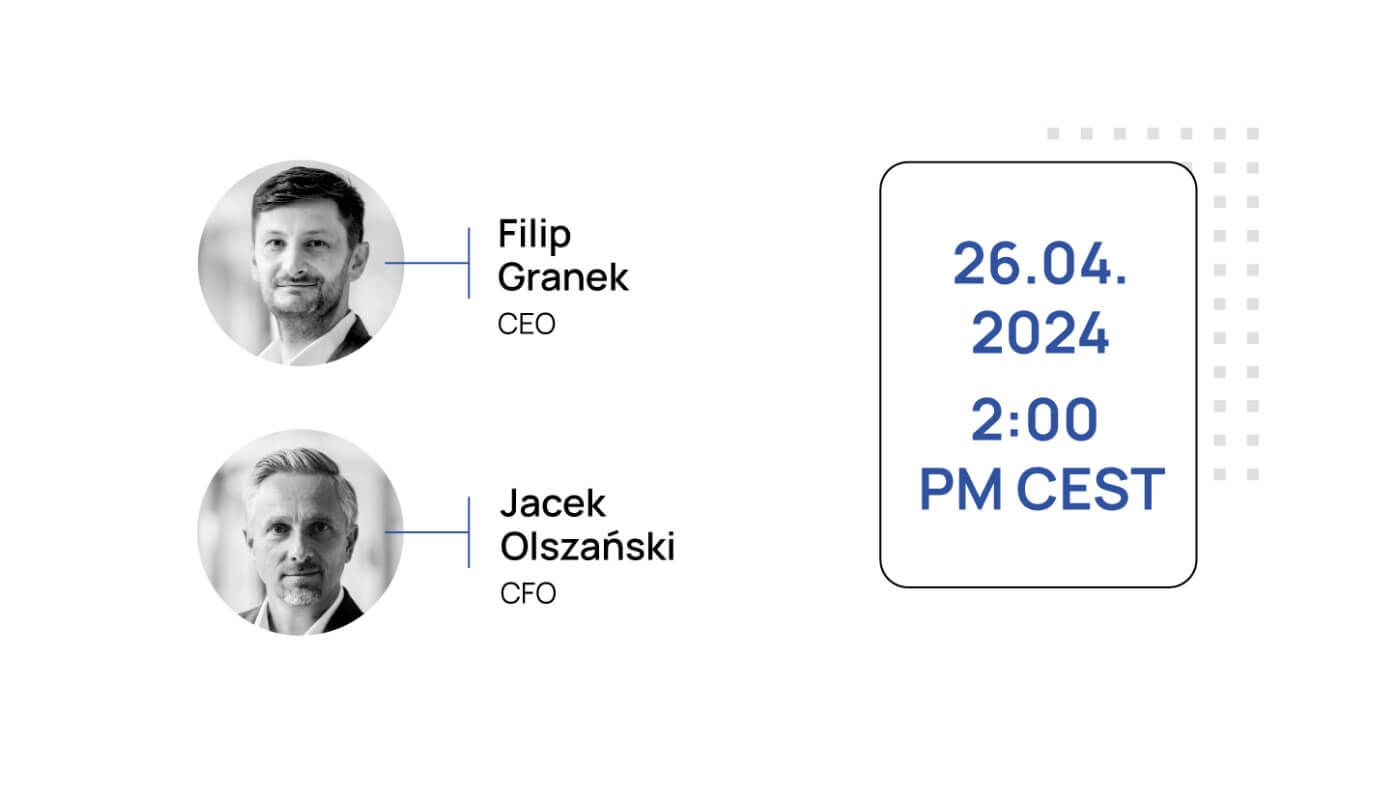

“In the coming months, we will deliver our module for industrial implementation to a Chinese partner active in the display industry, which is promising and strategic for XTPL. Our partner’s clients include leading manufacturers of modern FPDs for the Chinese market, such as an entity listed on the Shenzhen Stock Exchange with annual revenues in the order of several tens of billion USD. This is our first sale of a module to a partner in China and, as a result, XTPL is currently overseeing four advanced industrial implementation processes involving XTPL technology on key markets for additive technologies: China, USA, Taiwan and South Korea” says Filip Granek, CEO of XTPL S.A.

The XTPL industrial module is scheduled to be delivered to the company’s Chinese client within 3–5 months. Once delivered, the XTPL module will be used in the process of building an industrial prototype of the client’s device. XTPL expects the process to be completed by the end of 2024. The end buyer of the XTPL industrial module is a leading Chinese manufacturer of testing and repair equipment used in the production lines of advanced FPDs.

“This order is of vital importance to us for several reasons. The relationship with the Chinese partner was established through our distributor in the Chinese market, Yi Xin Technology. This is evidence that the international efforts of the XTPL distributor network can not only yield orders for Delta Printing System (DPS) devices, but also industrial implementation opportunities. It is worth noting here that the number of international distributors of XTPL solutions has doubled in recent months and now stands at 11. This also means a successful initial evaluation of our technology, which we completed in record time, around five months and similar to the implementation carried out for the US Nasdaq 100 manufacturer of large industrial equipment for next generation electronics manufacturers, we went straight to the fourth stage of evaluation and the construction of the prototype of an industrial device. All the previous processes lasted from one to several years. This is the outcome of a number of factors that we have worked hard to achieve in recent quarters while pursuing XTPL’s Strategy. The factors include the growing international visibility of XTPL, especially in the Chinese market where we have sold a total of 10 DPS devices, and the reputation of our distributor that gives us credibility in the eyes of our partners. Another factor is the valuable experience we garnered in the previous processes working with industrial partners, geared towards industrial implementations, which we are more and more able to translate into quick and efficient evaluations of our technology” adds Filip Granek.

Yi Xin Technology has been operating in the market since 2011. It specializes in additive technologies and the search for innovative solutions dedicated to the printed electronics segment. The firm has an extensive network of relationships with major Chinese research institutes and industrial manufacturers from the modern electronics sector.

XTPL’s business model is based on three complementary business lines. These are printing modules for industrial implementation on the production lines of global manufacturers of electronics, the Delta Printing System (DPS) prototyping devices, and High Performance Materials (HPM, nanoinks). The Company has a total of nine projects aimed at industrial implementation of its technology, four of which are at an advanced stage of development. They cover the areas the Company considers strategic: semiconductors and displays. The potential average annual revenues from all nine industrial projects being developed at present totals an estimated PLN 400 million. The Company’s end customers are global entities responsible for the production of next generation electronics, including a Chinese manufacturer of machines for the sector of modern displays, a leading semiconductor manufacturer from Taiwan, one of the world’s largest producers of FPDs (Flat Panel Displays) from South Korea and a top manufacturer of industrial machines from the United States, listed on the Nasdaq 100 index.

Additional information is available from:

Mardoniusz Maćkowiak | cc group

+48 605 959 539 | mardoniusz.mackowiak@ccgroup.pl

Małgorzata Młynarska | cc group

+48 697 613 709 | malgorzata.mlynarska@ccgroup.pl

Back to all articles

Back to all articles