HB Technology places another order for XTPL’s printing module as work on industrial implementation gains momentum

In the first half of 2024, XTPL is to deliver a second industrial module to its South Korean partner HB Technology. The cooperation is targeted at the industrial implementation of the XTPL technology on the production lines of the end customer – a leading global manufacturer of FPDs (Flat Panel Displays). The next order results from the successfully completed stage of building an industrial prototype of the device containing the XTPL module. In late 2023 and early 2024, HB Technology delivered the device to the end customer, where it was deployed and underwent first tests. The new order for the industrial module and the construction of a second prototype device is expected to accelerate further tests of the XTPL technology, conducted concurrently at HB Technology and at the end customer’s facility. HB Technology, listed on KOSDAQ in South Korea, is a manufacturer of equipment for testing and repairing devices for global display makers. Its customer base includes such names as: Samsung Display Corporation or Beijing BOE Display Technology.

As regards projects that are at an advanced stage leading to a potential industrial implementation of the XTPL technology, the end customers are global entities responsible for the production of next generation electronics, including one of the world’s largest producers of FPDs from South Korea, a leading semiconductor manufacturer from Taiwan and Nasdaq 100-listed top US manufacturer of industrial machines.

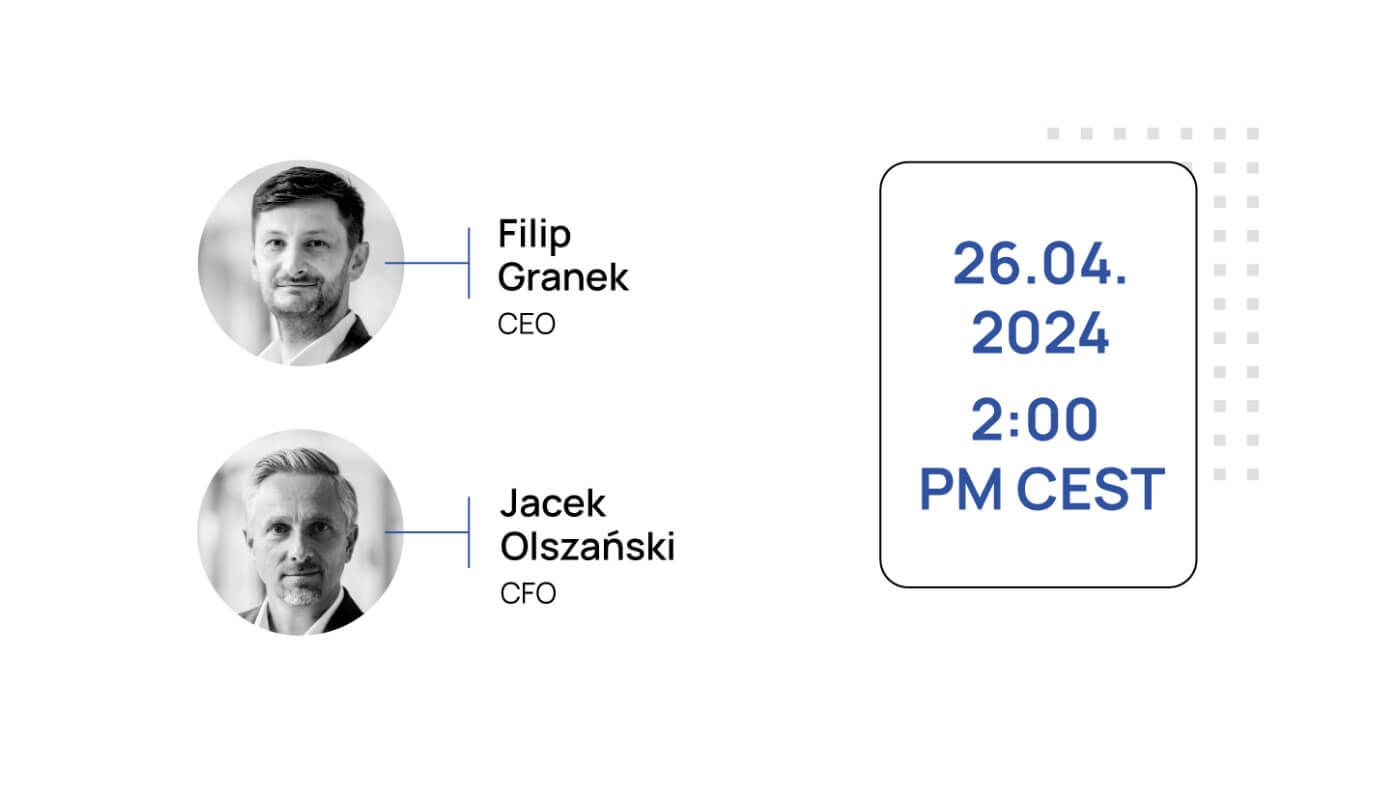

“Since 2024, the prototype of a large industrial device containing an XTPL module has already been in place at the end customer – one of the world’s largest display manufacturers. This is a major milestone in the fourth stage of the project aimed at industrial implementation. The ordering of another industrial module will accelerate further testing and the verification of compatibility of the XTPL technology with the specific requirements of the end customer. Please note that the whole process of evaluating our technology together with HB Technology and the end customer has been going on for about three years now, and each interaction with our partners gives us valuable insights and knowledge that we use to improve processes in our other industrial projects. I believe that this will contribute to the acceleration of subsequent implementations, and in the perspective of our 2023–2026 Strategy will bring a 10-fold increase in revenues from the sale of products and services to PLN 100 million by the end of 2026” says Filip Granek, CEO of XTPL S.A.

The XTPL industrial module is to be delivered to HB Technology in the first half of 2024. Once settled, the order will have a positive impact on the 2024 financial results, and will tighten the already long-standing cooperation and commercial partnership with HB Technology, which tests the potential of the Company’s technology also in other application fields beyond high-resolution FPDs.

HB Technology, listed on KOSDAQ (078150.KQ) in South Korea, is a manufacturer of equipment for testing and repairing devices for the most advanced display makers. HB Technology’s clients are the world’s leading manufacturers, including Samsung Display Corporation and Beijing BOE Display Technology. The XTPL solution can be used to repair advanced micro OLED displays, characterized by ultra-high resolution and located close to the human eye. These products are used in specialized medical and military equipment, as well as professional cameras, sky observation devices and smart glasses.

“We are particularly pleased with our progress in the area of modules for industrial implementation onto the production lines of global electronics manufacturers, as this will be the key driver of the Company’s revenues in the long-term vision of XTPL’s growth. Already in our 2023–2026 Strategy adopted last year, we assumed that the industrial projects line will contribute approx. 50% to our target of PLN 100 million in revenues from the sale of products and services. This requires a steady development of our projects geared towards industrial implementations, as well as investments in production capacity. We are happy to say that we are successfully following both of those paths, and are consistently working towards our goals. We trust that our efforts will result in XTPL becoming a globally recognizable brand, having a significant share in the value chain of next generation electronics that we will use on a daily basis” says Jacek Olszański, CFO of XTPL.

XTPL’s business model is based on three complementary business lines. These are printing modules for industrial implementation on the production lines of global manufacturers of electronics, the Delta Printing System (DPS) prototyping devices, and High Performance Materials (HPM, nanoinks). The Company has a total of nine projects aimed at industrial implementation of its technology, four of which are at an advanced stage of development. They cover three areas the Company considers strategic: semiconductors, displays and advanced PCBs. The potential average annual revenues from all nine industrial projects being developed at present totals an estimated PLN 400 million.

In 2022, the global value of the OLED industry was USD 38.4 billion (source: Precedence Research), and is expected to grow to USD 260 billion in 2032, that is at a CAGR of +21.1% in 2023–2032.

Back to all articles

Back to all articles