Third sale of the XTPL printing module for industrial implementation

XTPL’s cooperation with the South Korean partner is gathering momentum. Following the success of the third stage of evaluation of the Company’s technology, HB Technology from South Korea has decided to order the XTPL printing module to build a prototype industrial device. The end customer is a leading manufacturer of FPDs (Flat Panel Displays). The printing module is to be delivered in the third quarter of this year, and the construction of the industrial prototype of the device may be finalized later this year. The XTPL technology has the potential to be used in the fabrication of new generation ultra-high resolution displays, including the repair of advanced micro OLED displays. At the same time, HB Technology is conducting parallel tests using the XTPL Delta Printing System in two other areas of the potential application of the Company’s technology. In May this year, XTPL announced its plan to increase revenues 10 times to PLN 100 million by 2026. To achieve this ambition, XTPL intends to make investments of approx. PLN 60 million aimed at strengthening and accelerating the Company’s development, e.g. by increasing its production capacity, supporting sales activities and stepping up its R&D efforts.

In December 2022, XTPL announced the transition to the third stage of technology evaluation with HB Technology from South Korea and the start of preliminary talks on a prototype industrial device. Under the agreement, the Company provided the partner with the Delta Printing System (DPS) device in the first half of this year. Results of the tests completed to date by the partner in Korea, including with the use of the DPS, and consulted with the end customer, confirmed the high potential of the XTPL technology. On that basis, a decision was made to proceed to the fourth stage of the evaluation, namely the construction of a prototype industrial device.

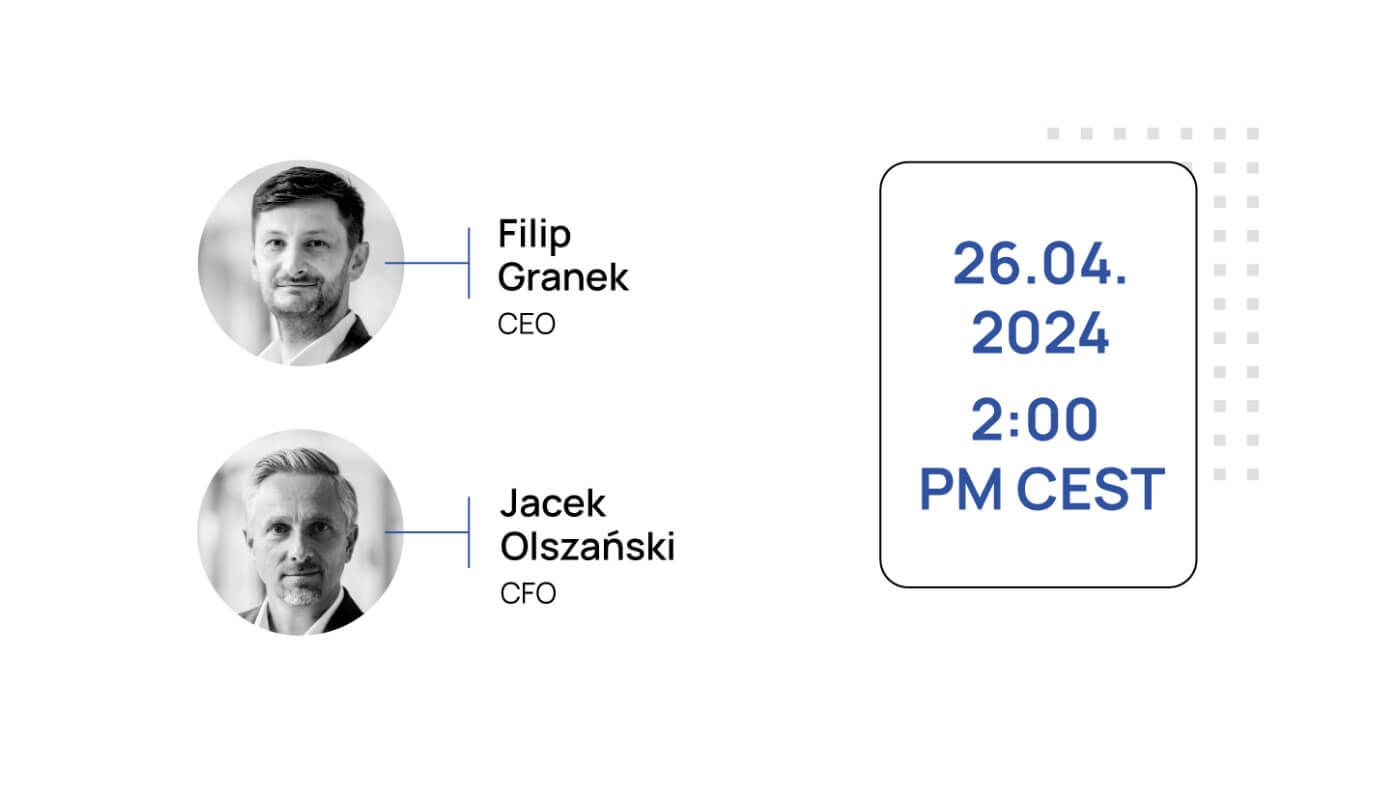

“We’re consistently moving forward with our advanced projects aimed at industrial implementation, and have already completed the third sale of the XTPL printing module for industrial implementations. After the very positive information about the transition to the fourth stage with a client, a global company from the United States listed on Nasdaq 100, now we are very happy to be able to announce the successful evaluation of the XTPL technology with HB Technology from South Korea. We have smoothly and successfully completed the third stage of the project and are moving on to the construction of a prototype industrial device that will contain the printing module supplied by us – the heart of the whole machine. Above all, I’d like to point to the potential application of our technology in the industry of high-resolution displays, which could be put to use in its fastest-growing areas, such as advanced medical and military devices and smart glasses. We see this as a highly interesting direction, which is additionally supported by global megatrends in the form of growing miniaturization of devices. Next generation, ultra-high resolution products need to be created and repaired differently than before. And this need will be accommodated by our unique, additive ultra-precise printing technology. The end customer is a leading manufacturer of FPD displays based in South Korea, and it is looking into the results of the tests conducted by XTPL and those carried out in Korea by the HB Technology team using our Delta Printing System device. I believe that the involvement of this global player at each stage of the evaluation may have a positive impact on the pace of the transition to the last, fifth stage, and in this way help achieve the first implementation of our technology on an industrial scale” said Filip Granek, CEO of XTPL.

The XTPL industrial module is to be delivered to HB Technology in the third quarter of this year. Once settled, the order will have a positive impact on the 2023 financial results, and the Company’s intention is to continue building the relationship and commercial partnership with HB Technology and with the end customer, a leading manufacturer of FPDs, in subsequent periods as well.

HB Technology, listed on KOSDAQ (078150.KQ) in South Korea, is a manufacturer of equipment for testing and repairing devices for the most advanced display makers. HB Technology’s clients are the world’s leading manufacturers, including: Samsung Display Corporation and Beijing BOE Display Technology. The XTPL solution can be used to repair advanced micro OLED displays, characterized by ultra-high resolution and located close to the human eye. These products are used, e.g. in specialized medical and military equipment, as well as professional cameras, sky observation devices and smart glasses. In 2021, the value of the OLED display industry was estimated at USD 38.4 billion and is expected to grow at the average annual rate of 13.6% in 2021–2026.

“Four of our projects aimed at industrial implementation are already at advanced stages. In this way, for 2023 we note the potential to build more than one prototype industrial device containing our proprietary industrial module. This vision and the growing interest in our technology and products have prompted us to accelerate the Company’s development and adopt the plan of investing approximately PLN 60 million in 2023–2026 in order to scale up our operations and attain our business goal – a 10-fold increase in revenues to PLN 100 million by 2026. The delivery of the industrial module as part of the transition to the fourth stage with HB Technology is not going to contribute more than several percent to our bottom line in 2023, but it does have a great potential to contribute more to our results in subsequent periods, including in the perspective of our goal for 2026. In addition, HB Technology is doing parallel tests using our DPS device in two additional application fields of our technology, other than micro OLED displays. These are only early stages of analysis, but they show the versatility and wide application of the technology that we have elaborated at XTPL over the last years and are now starting to successfully commercialize it on an ever-larger scale” adds Jacek Olszański, CFO of XTPL.

XTPL’s business model is based on three complementary business lines with a high potential to generate revenue streams, supported by R&D, and IP protection to maintain a long-term competitive edge. These are printing modules for industrial implementation on the production lines of global manufacturers of electronics, the Delta Printing System prototyping devices, and conductive nanoinks. The Company currently has 4 advanced projects geared towards industrial implementation of its technology. They cover all three sectors strategic for the Company: advanced PCBs, semiconductors and displays. The Company’s end customers are leading and global entities responsible for the production of next generation electronics, including one of the world’s largest producers of FPDs (Flat Panel Displays).

Since its inception, XTPL has been operating a carefully developed industrial and intellectual property protection policy, having 7 patents granted and a total of 26 patent applications filed from September 2019 to May 2023.

In 2021, the value of the rapidly growing printed electronics market was USD 47.1 billion (+14.5% YoY), while in 2025 it is forecast to grow to USD 63.3 billion (source: IDTechEx). This means an increase in the market value at a CAGR of 9.0% in 2020–2025. According to market analyzes, the market of electronic prototyping devices (the category that includes the Company’s DPS prototyping devices) is to see a CAGR of 31% in the years 2021–2031 (source: Transparency Market Research). Global annual sales of systems for R&D, rapid prototyping and small-lot production in the area of printed electronics sector amount to approx. 250–500 devices per annum, at a price of approx. EUR 50–500 thousand per device.

Back to all articles

Back to all articles