XTPL enters the key stage of an industrial implementation of its technological solutions into the industry of semiconductors manufacturing

XTPL S.A. (WSE: XTPL), a global supplier of ground-breaking nanoprinting solutions for the world’s modern electronics market, has announced its an order for delivery of a printing module for industrial integration for a partner from Taiwan. The XTPL printing module will be an essential element of the prototype of an industrial equipment for advanced packaging applications in the semiconductor industry. Execution of the order means progressing to the next stage of the advanced technology evaluation process focused on industrial implementation of XTPL’s technological solutions on the production lines of next generation electronics. The order was issued by a XTPL partner based in Taiwan, who is a manufacturer of specialized equipment for the production of semiconductors. The industrial device prototype will be tested on the production line of a leading global semiconductor manufacturer, also based in Taiwan.

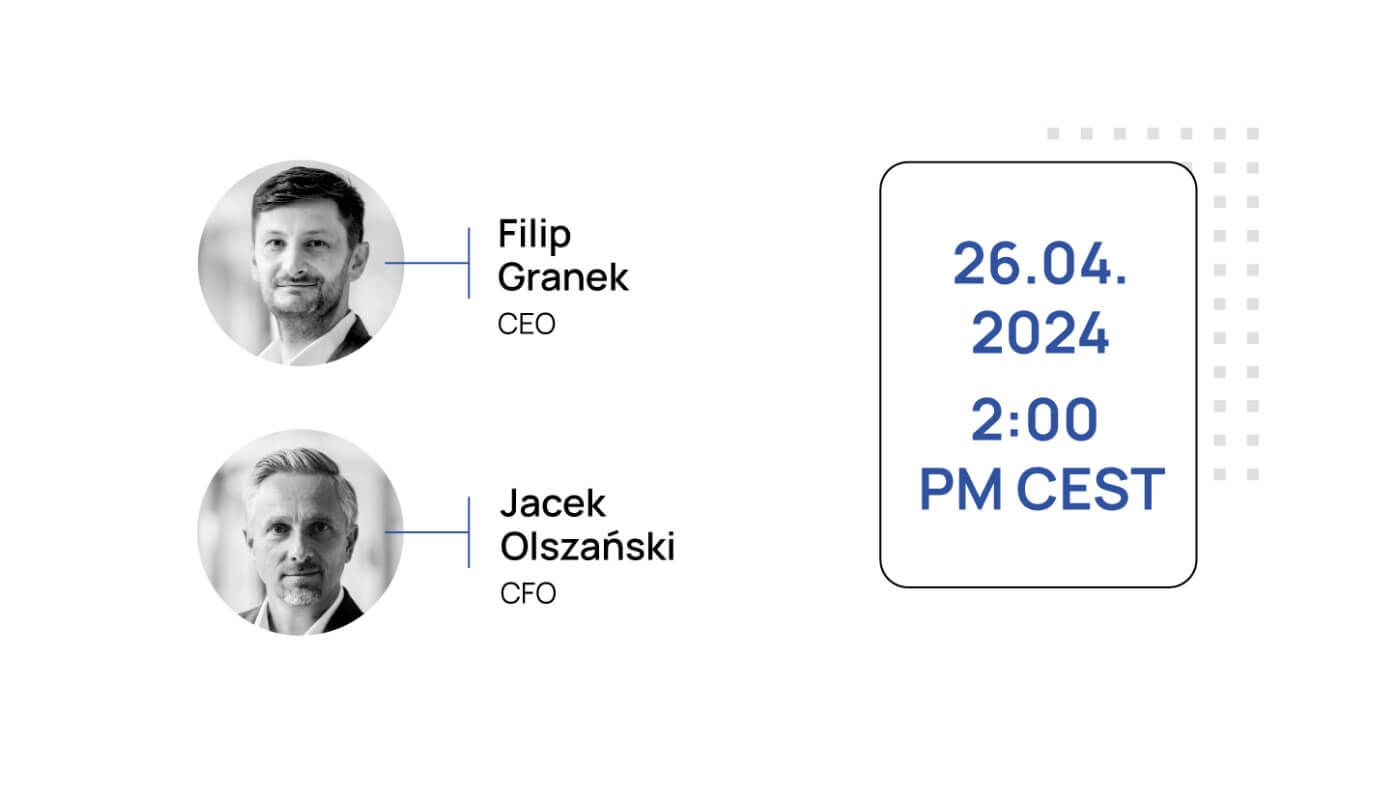

– We are very happy with the decision of our Taiwanese partner, who decided to order our solution following advanced and detailed evaluations of the XTPL technology. This is all the more pleasing because – in addition to the recently announced important relationship with the Israeli company Nano Dimension – it’s another industrial project taken to an advanced stage in the recent months. The adopted and consistently pursued commercialization strategy coupled with the engagement of the entire XTPL team yield tangible business results. We’re strongly moving closer to the introduction of XTPL technological solutions into the mass production of next-generation electronics – says Filip Granek, PhD, CEO of XTPL S.A.

In cooperation with XTPL, the partner from Taiwan, will build a prototype of an industrial manufacturing equipment for applications in the semiconductor industry. A unique XTPL printing module will be integrated into the device, and then the whole machine will be transferred to the end client, a leading global manufacturer of semiconductors, and will be deployed and tested on its production lines.

– Our solution for ultra-precise deposition of functional inks will be used in the construction of a prototype industrial device for use in the innovative semiconductor industry. This decision was taken following a complex evaluation process that lasted about 18 months, with multiple stages of testing and analysis of XTPL’s technological solutions in cooperation with our partner from Taiwan. It’s essential that the end client – a leading global semiconductor manufacturer, also Taiwan-based – was closely involved in the process of evaluation of the XTPL technological solution. The order for our printing module confirms the attractiveness of the technological solution offered by XTPL, and opens up the next stage of close cooperation with our Taiwanese partner, geared towards development and implementation of the equipment on the client’s production lines. It also confirms the potential of the commercialization of the XTPL technology in the frame of our most important business line, which is focused on industrial implementation of technological solutions developed by our company – adds the CEO of XTPL.

Revenue from the order will be recognized by the end of 2022.

The semiconductor market is one of the target markets for the XTPL technology. Its special application areas include making electronic connections on complex 3D topographies and heterogeneous substrates in advanced integrated circuits or microelectromechanical systems (MEMS). According to an analysis carried out by Mordor Intelligence that takes into account the impact of the COVID-19 pandemic, in 2020, the global market for advanced integrated circuits reached USD 24.9 billion, and by 2026 is expected to grow even to USD 38.6 billion. The size of this market shows great possibilities: not only in terms of potential application of the UPD technology in new areas, but also in the research and prototyping of new systems.

XTPL develops and commercializes three complementary business lines based on its proprietary UPD technology, each of which can generate independent revenue streams: printing modules intended for industrial implementation on the production lines of global manufacturers of next-generation electronics, the Delta Printing System prototyping devices, and conductive nanoinks. All the indicated technological solutions are based on the Company-developed conductive structure deposition technology. The technology responds to the three megatrends in the production of modern electronics. The industry is currently strongly focused on further miniaturization of the size and weight of electronic devices, modifying their forms and properties, and moving towards an increased flexibility and three-dimensionality. The recent global trend is also environmental protection by efficient use of limited resources while reducing the production waste, which is enabled by additive technology.

Back to all articles

Back to all articles