UNIQUE FEATURES

- superior printing stability – over 1 month of continuous work with repeatable results, and without clogging of the nozzles, even with the smallest 1 pL cartridges available for Dimatix DMP-2850 Printer

- high electrical conductivity – over 40 % of bulk Ag conductivity

- compatibility with various substrates – performance demonstrated e.g. on PET, PEN, PEI, glass substrates

TECHNICAL PARAMETERS

| Silver content (wt.%) | 34 ± 2 |

| Density [g/cm3] | 1.2 - 1.4 |

| Average nanoparticles size [nm] (TEM) | 35 – 50 |

| Shape of nanoparticles | Spherical |

| Electrical resistivity [Ω.m]* | 3.95 ∙ 10-8 |

| Viscosity (25°C, shear rate = 40 s-1) [cP] | 26 - 30 |

| Surface tension [mN/m] (25°C) | 30 |

| Solvent(s) | Glycol ether |

| Download Technical Data Sheet | IJ36 TDS |

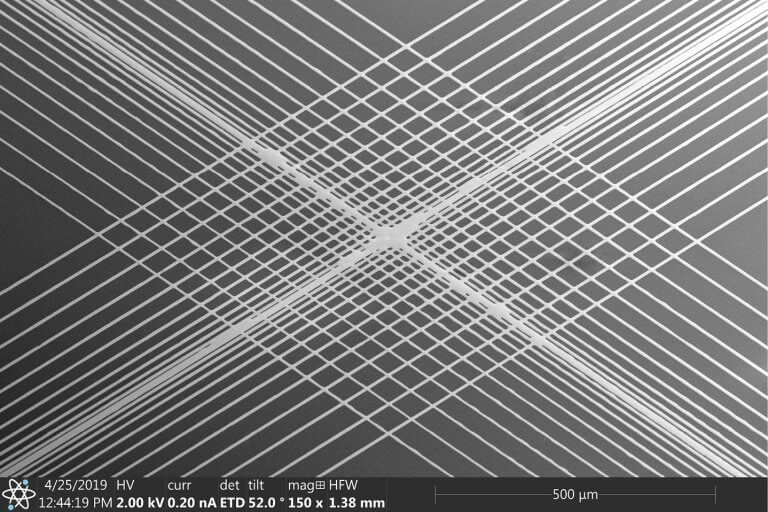

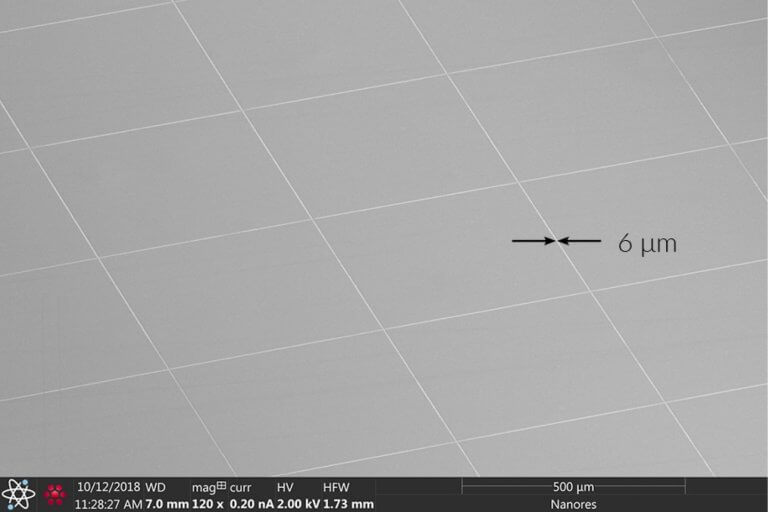

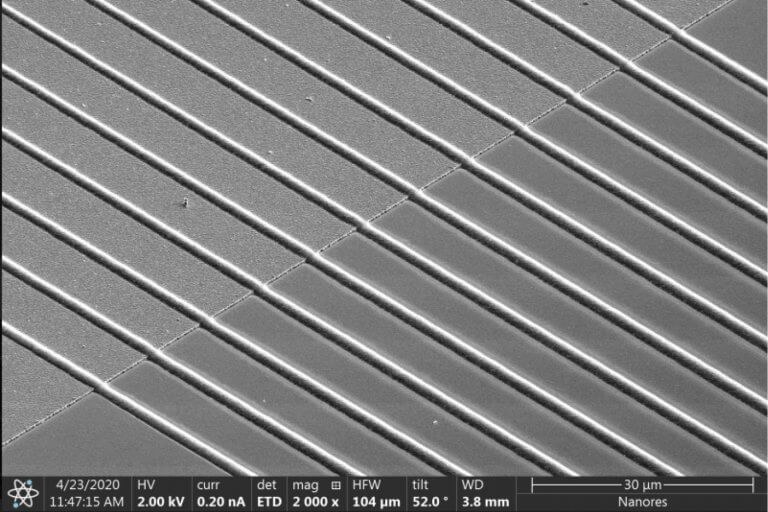

Optical microscope images of printed features (1 pL cartridge – Dimatix DMP-2850 Printer)

Example of printed structures on flexible foil using IJ36 (1 pL cartridge – Dimatix DMP-2850 Printer)

Suitable for

TESTIMONIALS

CONTACT US

Do you have questions regarding the specifications of our nanoinks? Do you want to place an order, or enquire for a customized one? We are at your disposal and always happy to help.

We will answer all technical questions, present our products and help you to choose the nanoink that best suits your needs. Fill out the contact form. Our Business Development department will contact you as soon as possible.

Direct contact person:

DARIA WIĘCŁAWSKA

Business Development Specialist

Read more

Read more

REQUEST QUOTATION

REQUEST QUOTATION