XTPL will deliver its Delta Printing System to University of Stuttgart

- XTPL is carrying out its first commercial contract for an UPD technology demonstrator – XTPL Delta Printing System for precise printing of micro-features, including conductive structures.

- The contract was signed with the University of Stuttgart, Institut für Großflächige Mikroelektronik “IGM”

- The researchers led by Prof. Fruehauf at the University of Stuttgart will use the XTPL’s Delta Printing System to demonstrate a fully-printed, high-resolution flat panel display (FPD).

XTPL will deliver its Delta Printing System to the Institute for Large Area Microelectronics (Institut für Großflächige Mikroelektronik “IGM”) at the University of Stuttgart.

Delta Printing System uses the XTPL’s proprietary Ultra Precise Deposition (UPD) technology and is a high-precision rapid prototyping printing system for microelectronics with the capability of printing ultra-fine features down to 1.5 micrometre.

The Institute for Large Area Microelectronics (IGM) of the University of Stuttgart (Germany) led by Prof. Norbert Fruehauf is a research and education institute specialized in novel processes and materials for advanced flat panel display technology (FPD). Current research at the institute focuses on organic light-emitting diodes (OLEDs) and thin film transistors (TFTs) for advanced and flexible displays. IGM was designed with a major focus on application-oriented research and transferability into commercial fabrication processes. Since its foundation IGM has achieved numerous successes in research and has an excellent reputation over the world.

“We observe and confirm the global technological trend is moving towards further miniaturization and increase in resolution of display technologies. We are looking forward to the delivery of the XTPL Delta printing system to our clean-room pilot line of advanced flat panel display manufacturing and to continue collaboration with the XTPL team. The XTPL’s ability to directly deposit (in a mask-less approach) electrically conductive structures in the minimum feature size range of 1.5 – 10 micrometers is unique. In my view the XTPL’s ultra-precise deposition technology offers truly unique properties, which are an excellent fit to the future needs in the field of printable high-resolution and foldable OLED displays.“ – explained Prof. Norbert Fruehauf, director of IGM.

The researchers led by Prof. Fruehauf at the University of Stuttgart will use the XTPL’s Delta Printing System to demonstrate a fully-printed, high-resolution display. This will be possible thanks to the unique possibility of repeated printing of conductive structures as small as 1.5 µm in size.

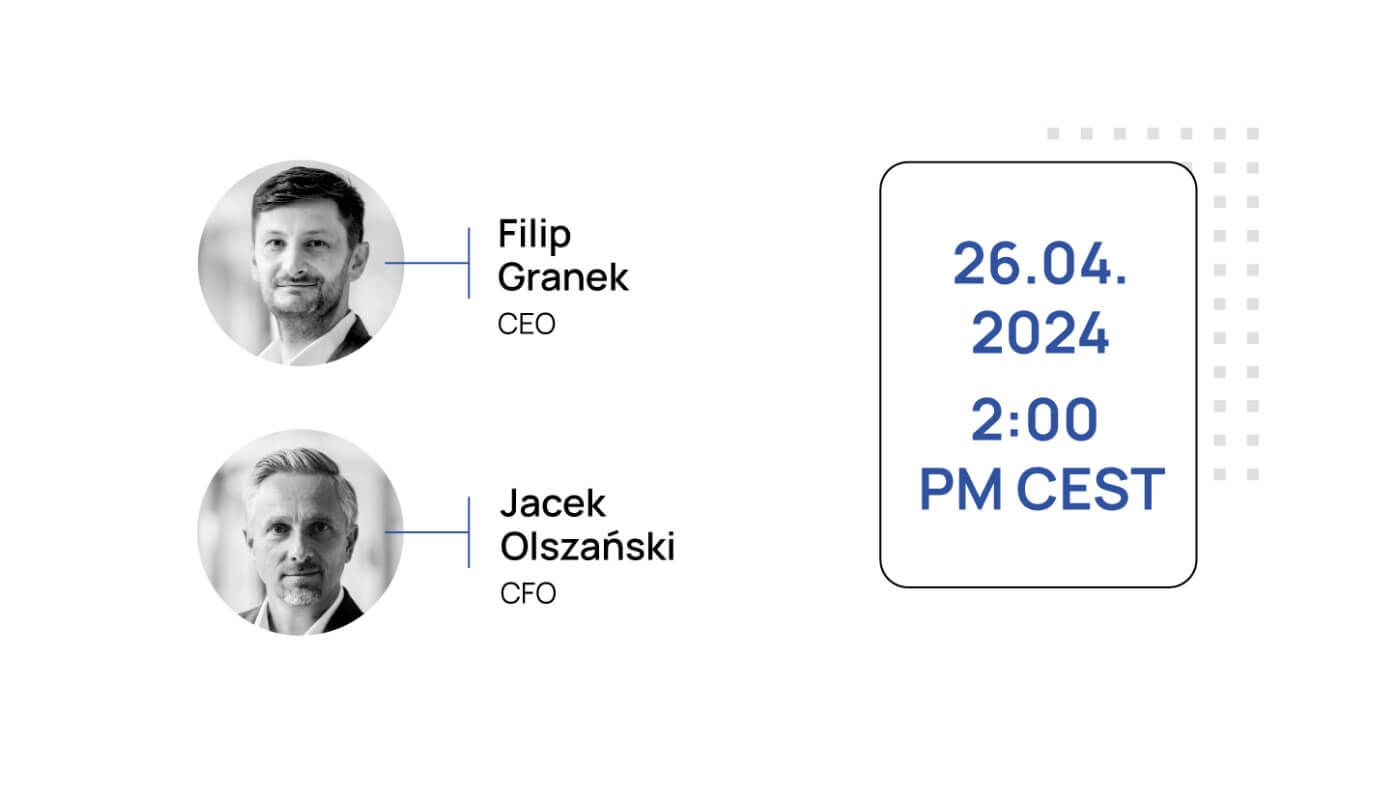

“We are very happy about the collaboration with IGM led by prof Fruehauf. IGM is a leading research institution in the area of advanced FPDs, and collaborates closely with global leaders of the FPD industry. The contract to deliver our first Delta Printing System to IGM is a significant milestone in commercialization efforts of our proprietary UPD technology. IGM’s decision confirms our high technology readiness level and attractiveness of its unique properties in the field of FPD advancements.” – said dr Filip Granek, CEO of XTPL.

The contract provides for leasing the XTPL demonstrator with a purchase option. The maximum contract value is approx. EUR 190 thousand net (approx. PLN 880k net). The delivery of the Delta System to IGM is scheduled in 2020. The figure does not include the supply of consumable materials such as cartridges, inks and nozzles which will be supplied to IGM by XTPL.

XTPL offers its technology demonstration system to both academic and corporate research centres active in the field of advanced microelectronics and flat panel displays. XTPL is under advanced talks with multiple partners about the delivery of Delta Printing Systems.

Back to all articles

Back to all articles