XTPL and the University of Brescia start work on next-generation bioelectronics

XTPL S.A., a global supplier of breakthrough nanoprinting solutions for the world’s electronics market, has begun strategic cooperation with the Department of Information Engineering of the Italian University of Brescia (UniBS). Over the following two years, the Company will work together with the local scientists on the application of XTPL technological solutions in the biosensor industry.

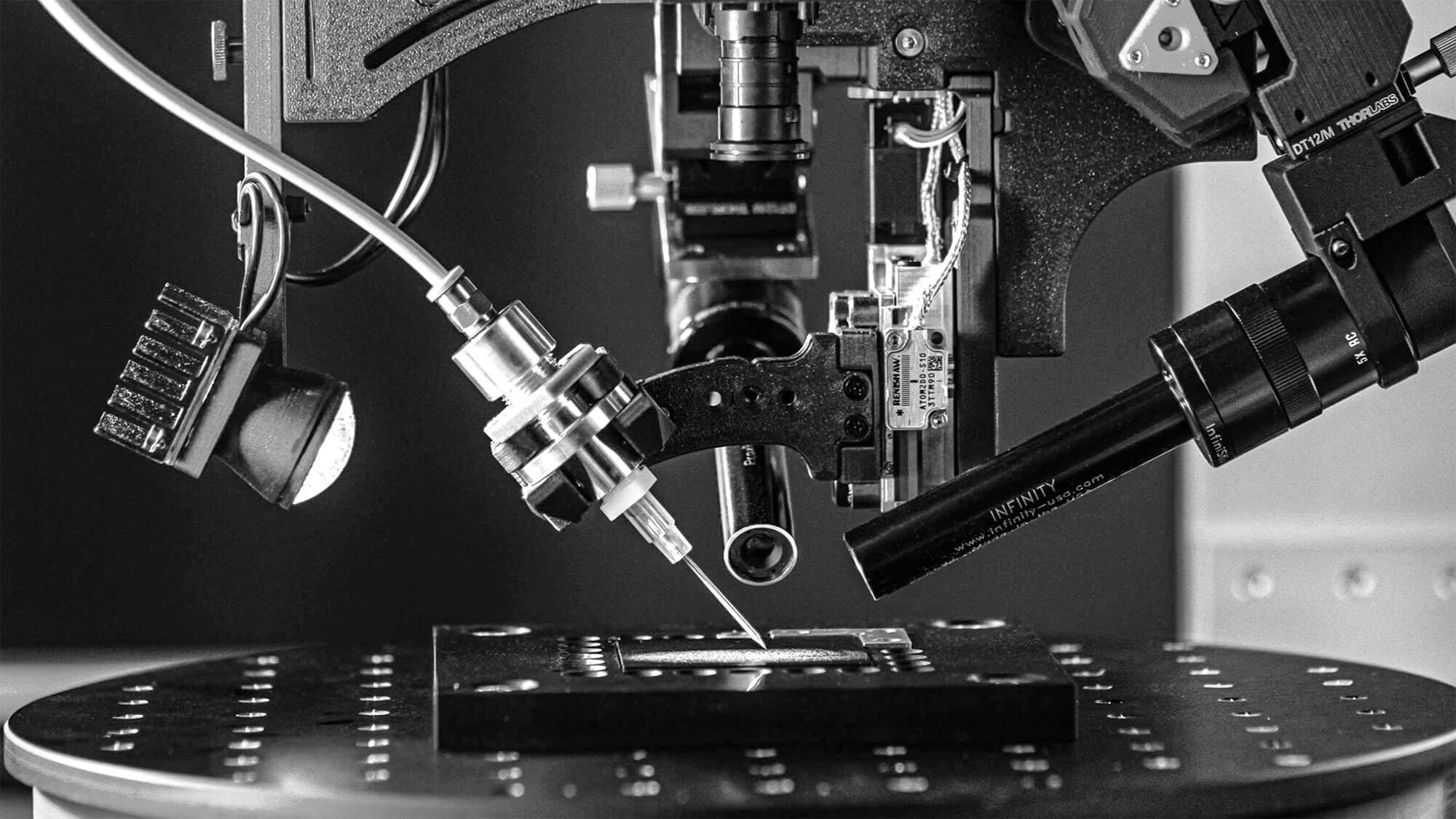

In December 2021, the Department of Information Engineering (Dipartimento di Ingegneria dell’Informazione – DII) from the University of Brescia purchased from the Company its Delta Printing System, which is now used by the local team in research on the organic biosensor matrix, among other things.

The purpose of the strategic cooperation with UniBs is to develop an innovative method of producing next-generation organic biosensors using the unique electronics printing technology created by XTPL. As part of this initiative, the Company will ensure extensive technological and expert support relating to its proprietary technology and the Delta Printing System. On the other hand, the DII will provide XTPL with information on the results of its work and outcomes of microproduction of printed biosensors integrated with 3D, adaptable, and flexible substrates. The information will be based on feedback received from industry partners with whom the DII’s research team has built strong relationships. In addition, results of the research will be published in publicly available scientific articles and presented at the most important international scientific conferences. Reaching out to a new group of industrial recipients will allow XTPL to bring its technology solutions to another segment of next-generation electronics.

“Already some time ago we noted that the biosensor market may be one of the most exciting applications for the XTPL technology of printing electronics using the additive method. However, Professor Torricelli outlined the potential of this industry in more detail for us. Establishment of the relationship not only supported and gave impetus to the research work with UniBs through the sale of the Delta Printing System, but also allowed us to move a step forward and decide about joint R&D on implementation of the XTPL technology in the microproduction of bioelectronics planned by Professor Torricelli,” says Filip Granek, CEO of XTPL S.A.

“Once we got to know the capabilities of the XTPL technology, we decided to purchase the Delta Printing System in the first place. The more familiar we became with the Company’s solution, the more convinced we grew about forging a longer cooperation with XTPL and working together on what we believe is a promising solution for bioelectronics. We intend to develop ultra-sensitive, organic biosensors that will be printed and integrated into 3D, adaptive and flexible substrates. A significant market advantage for these new biosensors will be their biodegradability, an important and increasingly necessary feature of electronic devices,” says Fabrizio Torricelli, Professor at the University of Brescia, who leads the research.

The parties to the agreement also consider expansion of the cooperation under international projects funded as part of selected EU programs.

The first simple biosensors were developed in the 1950s. They were used to measure the level of oxygen and glucose in human blood. Bioelectronics enables the creation of medical devices that improve life quality for sick and disabled people. Bioelectronic inventions include, for example, a glucometer and electrodes stimulating various types of systems (e.g. the neurological system in epilepsy, auditory system in deaf people) and supporting the treatment of chronic pain or arthritis. Modern biological sensors are expected to become the standard in patient diagnostic tests and in monitoring their health. As an element of the personalized medicine tools system, they will simplify and increase the availability of many therapies.

The global biosensors market in 2021 was estimated at USD 25.5 billion, and is to reach USD 36.7 billion by 2026. Its CAGR is expected to stand at 7.5% between 2021 and 2026 (source: Markets and Markets Research). Analysts pointed out that the key drivers for the growth of this market include: the emergence of nanotechnology-based biosensors, the increasing incidence of infectious diseases and civilization diseases such as cardiological complications, diabetes, and the current COVID-19 pandemic, which increases the need for point-of-care diagnostics and home care.

The XTPL technology is a response to the three megatrends in the production of modern electronics. The industry is currently strongly focused on further miniaturization of the size and weight of electronic devices, modifying their forms and properties, and moving towards an increased flexibility and three-dimensionality. The recent global trend is also environmental protection by efficient use of limited resources while reducing the production waste, which is enabled by additive technology. XTPL develops its proprietary innovative nanoprinting solutions that support those trends, offering them to global players in the rapidly growing printed electronics industry. In 2020, its value was USD 41.2 billion (+11.0% YoY), and in 2025 it is forecast to grow to USD 63.3 billion, while 2030 it is expected to reach even USD 74.1 billion (source: IDTechEx). This means an increase in the market value at a CAGR of 9.0% in 2020–2025.

Back to all articles

Back to all articles